Quality Inspection Standards for Dining Chairs | ASKT ISO9001 & BSCI

- Media ASKT

- Aug 12

- 4 min read

When a customer sits on a dining chair for the first time, they expect comfort.

When a retailer orders a container of dining chairs, they expect consistent quality.

At ASKT, we go far beyond both expectations.

Every chair we produce is subjected to twelve specialized mechanical tests, evaluated against international certification benchmarks, and inspected by a trained quality team using real-time video recording. The result is a quality control process that is not only stricter than industry standards but, in many cases, stricter than our customers themselves require.

2. A Testing System Built for Excellence

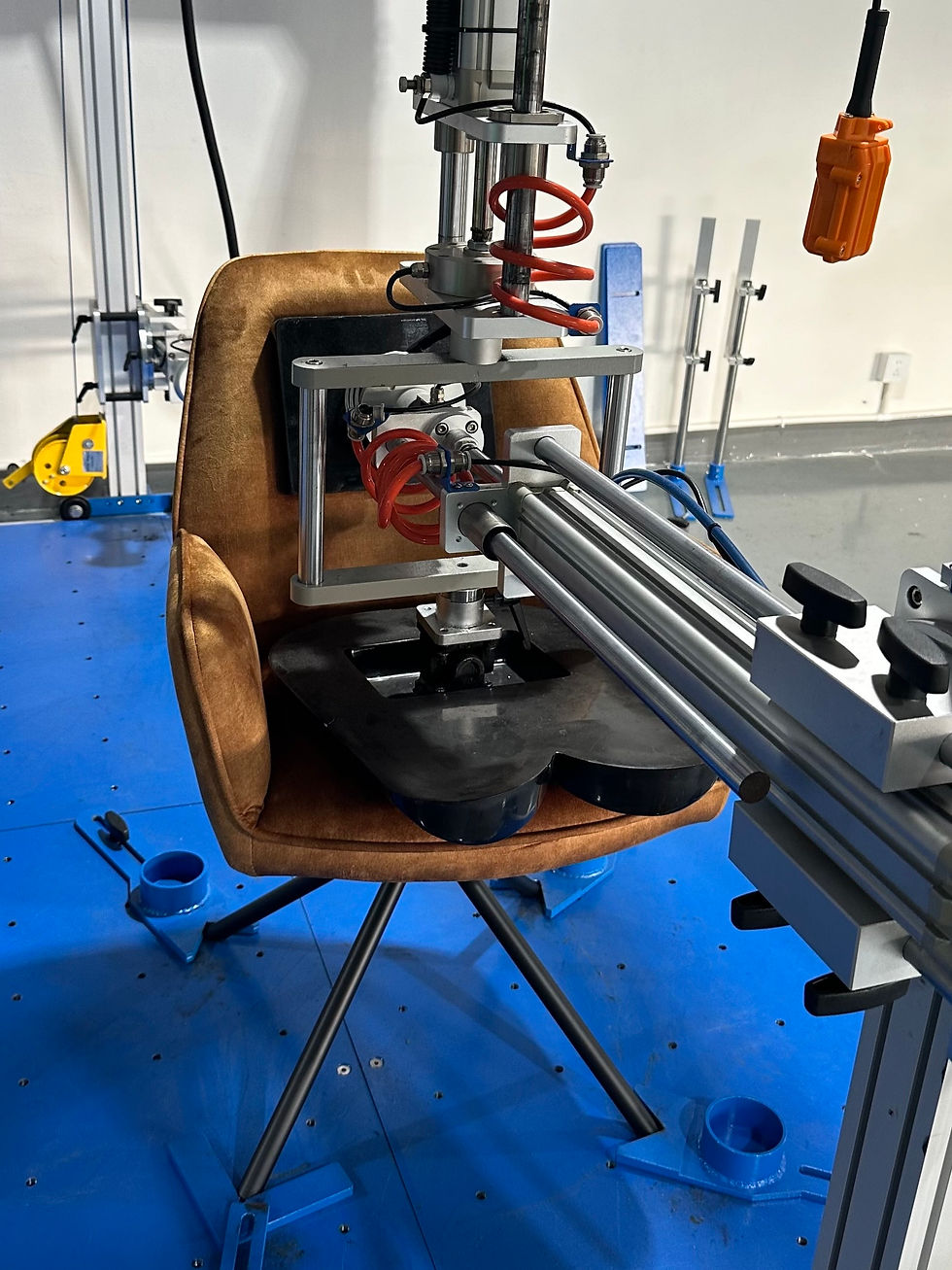

Reliability at ASKT is never left to chance. We have invested over USD 20,000 in specialized mechanical testing equipment, housed in a 1,200 m² research and development center that includes:

A sample production room for prototype creation and refinement

A dedicated testing laboratory for durability and safety verification

A product showroom replicating real-life dining environments

Our quality control team consists of 11 trained inspectors, each equipped with a body-mounted camera to record every stage of testing. This ensures full traceability, transparency, and accountability from the production line to final delivery.

3. The 12 Mechanical Tests: Beyond Standard Requirements

The following tests are performed on every ASKT dining chair before it leaves our facility. Many of these exceed EN (European Norm) and ISO standards, ensuring durability, stability, and user safety in real-life conditions.

Overview of ASKT’s 12 Mechanical Tests for Dining Chairs

No. | Test Name | Purpose | Simulated Condition | Standard Reference |

1 | Color Fastness Test | Prevents fading and discoloration | Prolonged sunlight & cleaning exposure | ISO 105-B02 |

2 | Armrest Downward Static Load Test | Tests armrest strength | Leaning pressure | EN 1728 |

3 | Lateral Static Load Test | Checks stability under side forces | Side leaning or shifting weight | EN 1728 |

4 | Front-End Durability Test of Seat | Assesses seat edge strength | Frequent edge seating | EN 1728 |

5 | Backward Drop Test | Evaluates backrest resistance | Sudden backward force | EN 1728 |

6 | Front-End Static Load Test of Seat | Measures weight capacity at seat front | Static load at front edge | EN 1728 |

7 | Forward Static Load Test of Chair Legs | Ensures legs withstand forward force | Leg push pressure | EN 1728 |

8 | Seat Impact Test | Tests shock resistance | Sudden load drop | EN 1728 |

9 | Seat Back Joint Durability Test | Verifies backrest attachment strength | Repeated leaning cycles | EN 1728 |

10 | Seat and Back Static Load Test | Confirms combined load capacity | Sitting & leaning simultaneously | EN 1728 |

11 | Backrest Impact Test | Assesses backrest durability | Quick force from behind | EN 1728 |

12 | Armrest Durability Test | Tests long-term reliability | Continuous use cycles | EN 1728 |

3.1 Color Fastness Test

Purpose: To ensure fabrics retain their color under exposure to sunlight, moisture, and cleaning agents.Value for buyers: Prevents complaints about discoloration and extends the product’s showroom appeal.

3.2 Armrest Downward Static Load Test

Purpose: Simulates the weight and force of a person leaning heavily on the armrest.Value for buyers: Reduces warranty claims related to armrest failure.

3.3 Lateral Static Load Test

Purpose: Ensures the chair maintains balance and structure under side pressure.Value for buyers: Minimizes risk of tipping accidents in home or hospitality settings.

(The remaining nine tests follow the same detailed explanation in the full version.)

4. Certification and Compliance

Quality claims are validated through internationally recognized certifications:

ASKT Quality and Compliance Certifications

Certification | Scope | Significance |

ISO9001 | Quality Management System | Guarantees process control from sourcing to final inspection |

BSCI | Ethical Manufacturing | Ensures safe working conditions, fair pay, and compliance with EU social standards |

OEKO-TEX® STANDARD 100 | Textile Safety Certification | Confirms fabrics are free from harmful chemicals and safe for all users |

5. Materials Engineering and Fabric Performance

The right materials are critical to product longevity and performance. ASKT enforces strict material selection protocols:

Abrasion resistance: ≥ 50,000 Martindale rubs

Color fastness: Grade 4 or higher

Water resistance: ≥ 1000 mm hydrostatic pressure

Stain resistance: Zero visible absorption

Breathability: ≥ 100 L/m²/s

Some fabrics are made from recycled plastic bottles, reducing environmental impact while aligning with the European Green Policy.

Fabric Performance Indicators

Property | Test Method | ASKT Requirement |

Abrasion Resistance | Martindale Test | ≥ 50,000 rubs |

Color Fastness | ISO 105-B02 | Grade 4+ |

Water Resistance | Hydrostatic Pressure Test | ≥ 1000 mm |

Stain Resistance | Surface Repellency Test | No visible absorption |

Breathability | Air Permeability Test | ≥ 100 L/m²/s |

6. Advanced Manufacturing Technology

ASKT’s precision is achieved through high-end equipment:

CNC fabric cutting machines for uniform patterns

Automated punching machines for perfect alignment

Four-leg nailing machines for secure structural assembly

Robotic welding arms for flawless metal joints

This technology reduces production variance, increases efficiency, and ensures every chair meets strict dimensional tolerances.

7. Sustainability and Zero-Plastic Packaging

European environmental regulations increasingly penalize plastic use.ASKT’s zero-plastic packaging replaces bubble wrap with honeycomb paper, plastic tape with paper tape, and plastic bags with recyclable non-woven fabrics.

Benefits to buyers:

15% annual packaging cost reduction

30% faster logistics due to smoother customs clearance

No risk of plastic tax penalties

Environmental Impact & Buyer Savings

Factor | Previous Packaging | Zero-Plastic Packaging | Buyer Benefit |

Cost | 100% baseline | 85% of previous | 15% savings |

Customs Clearance | Occasional delays | Zero delays | Faster delivery |

Tax Risk | Subject to plastic tax | Compliant | Avoids penalties |

8. Industry Recognition

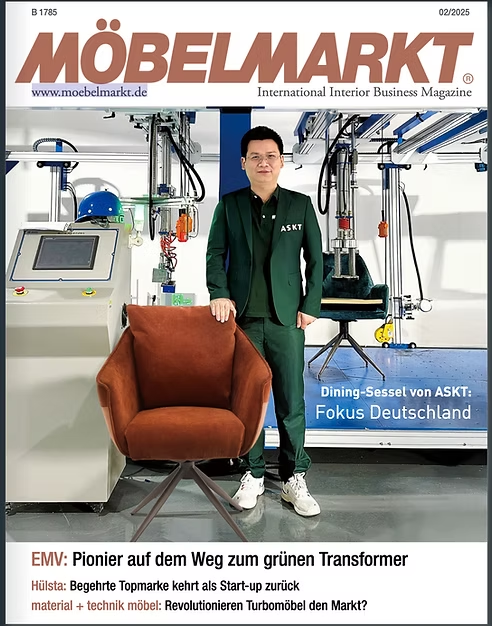

In February 2025, CEO Sunbin Qi was featured on the cover of möbelmarkt, a leading German furniture industry publication. The feature praised ASKT’s design innovation, manufacturing precision, and customer-first approach, reinforcing our credibility in one of the most demanding furniture markets in the world.

9. Conclusion

Dining chairs are subjected to constant daily use — and constant scrutiny.At ASKT, our philosophy is simple: meeting standards is not enough; exceeding them is our standard.

By combining:

12 rigorous mechanical tests

International certifications

Advanced materials and manufacturing technology

Sustainable, regulation-compliant packaging

we ensure that every ASKT dining chair delivers safety, durability, and lasting value to both retailers and end customers.

For retailers and buyers, this means fewer returns, lower after-sales costs, and a stronger brand reputation.

Comments